Automation

The k-tech automation technology – individual, reliable and efficient

We rely on the latest technology for our automation systems

In a world of progressive automation and digitization, the use of electrical and control components has become vital. Production systems are becoming more and more complex and, it is more difficult to keep track of the resulting flood of data. The challenges are: A wide variety of drive systems, controls, safety solutions, communication levels, interfaces and management systems must be combined with one another.

Our engineers and technicians will be glad to help you find the simplest and most efficient control possible for your project.

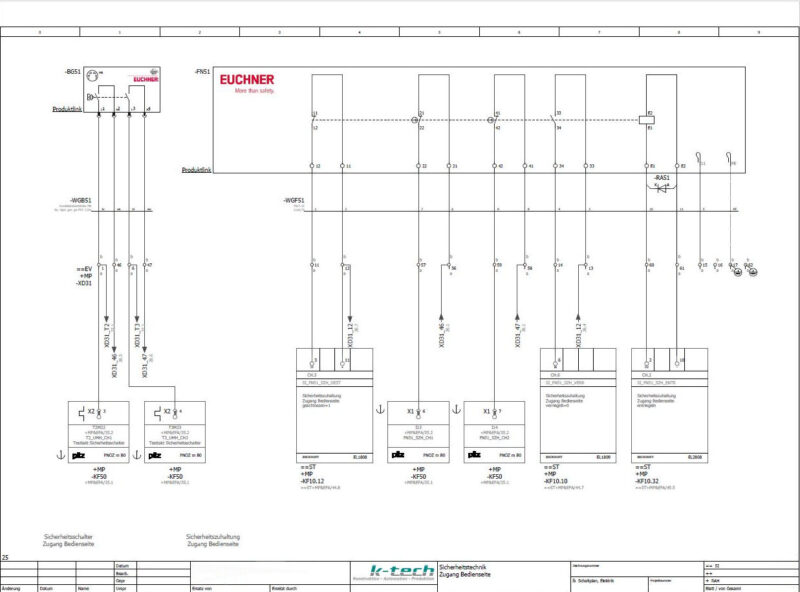

Hardware engineering

A wide variety of components are used in mechanical engineering: Drive technology, pneumatic systems, sensors, safety technology, camera systems, dosing and metering systems and, much more. For the electrical connection and supply of all these, k-tech relies on proven components and technologies.

Using monitored power supplies and intelligent automatic circuit breakers, we ensure that the system operates in a protected and transparent manner. For the conception and documentation, k-tech uses proven planning software like EPLAN and WSCAD. A wiring diagram allows to realize the control cabinet in a targeted manner and, to find faults faster when troubleshooting.

Benefit from our know-how in the field of automation and implement your project together with us.

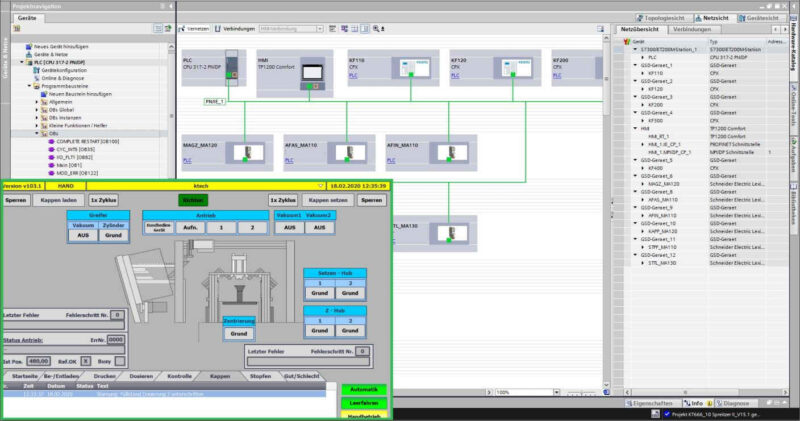

PLC and HMI programming

With Siemens and Beckhoff (Codesys based user interface), k-tech uses two of the most popular and most reliable control systems. Bus systems such as Profinet and EtherCAT can be easily integrated. With „Structured Text“, we benefit from the advantages of object-oriented programming in order to be able to realize even more complex tasks efficiently and clearly.

To operate the system, manage data and display various status information, we create an appropriate user interface (HMI) in cooperation with you. In addition to the classic I/O interface, OPC-UA or a message-based TCP/IP protocol are used to connect other equipment and systems. On your request, we also use other systems and interfaces.

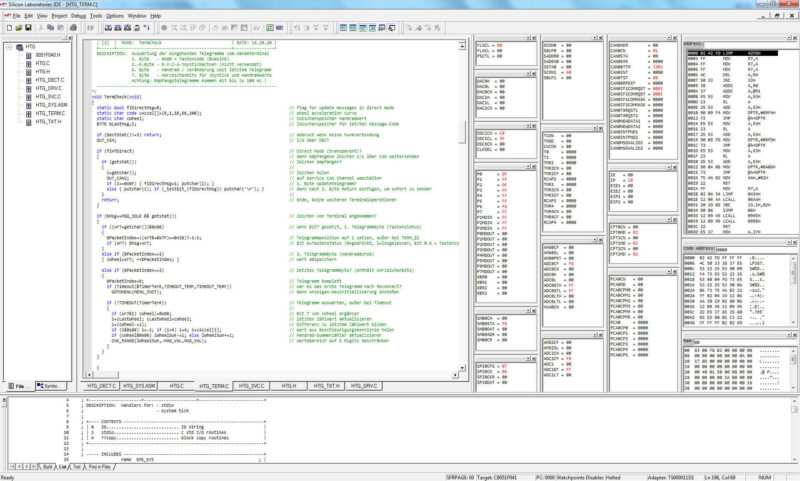

Microcontroller programming

Sometimes a PLC is not suitable as a control element, e.g. to a low voltage level, lack of space, costs or speed. In this case, k-tech will use the benefits of a microcontroller. In cooperation with an in-house partner, the required hardware can be realized. Analogue and digital technology can be used to implement various requirements on a custom circuit board.

Robotics

The use of robots in industry is gaining in importance. Since k-tech aims to always be technically up to date, we are increasingly using robots from different manufacturers for special machines. Benefit from our experience in the field of automation: In addition to the mechanical integration into the system, we also offer the electrical and safety-related connection, robot programming and, integration with the PLC. Whether Scara, 5- or 6-axis robots – we will be glad to support you in the choice of the right robot type and the most suitable size. We work with the following robot manufacturers, among others:

Cooperations with robot manufacturers

- Epson

- Kuka

- Stäubli

- Nachi

- Mitsubishi

- Universal Robots

- ABB

- Denso

- Fruitcore Robotics

- Others on request

Control cabinet manufacturing

Whether for small systems or larger equipment – we ensure the customized assembly and wiring of your control cabinets. It does not matter whether the control cabinet is part of a special machine, or you need a single or multiple control cabinets for your own application. Also in this respect, k-tech can support you as an extended workbench. Our service includes checking the control cabinets in accordance with the applicable VDE guidelines before delivery.

Installation & commissioning

To be able to deliver a perfectly functioning machine, we carry out various tests and controls of the linked processes. This includes the basic tests according to VDE to guarantee the electrical safety of the machine, as well as general and project-specific functional tests.

After delivery of the system, we will be happy to support you on site with the installation and alignment, commissioning, and integration with your infrastructure. Final functional tests ensure the safe operation of the system and a stable production process.

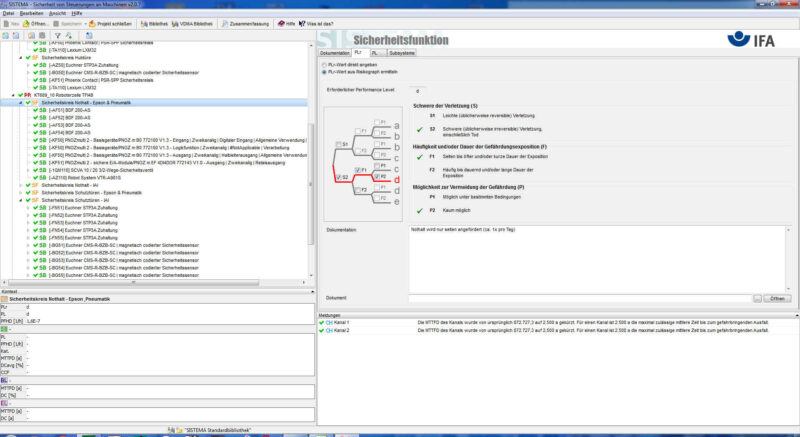

Safety technology

In order to be able to operate a CE-compliant system, it is necessary to install appropriate safety technology to protect people and machines. k-tech can draw on many years of experience in various areas of security technology and, will be glad to support you in implementing the optimal security solution. We develop, assemble, wire, and test the security system for you. For this purpose, we only use proven and tested safety components from the following manufacturers:

Cooperations with manufacturers of safety components

- Pilz

- Elobau

- Ifm

- Schmersal

- Euchner

- Sick

- Beckhoff & Siemens

- Omron

- Phoenix Contact

- Eaton

Analysis & concepts of safety solutions

Do you need support in developing a safety concept or do you want to take a closer look at an existing concept? k-tech will be happy to advise you, because we know: Safe, efficient, and ergonomic work must be guaranteed, especially in the area of safety technology. We are also glad to carry out a risk analysis in accordance with ISO 12100, as well as an assessment of machine safety in accordance with ISO 13849 with the „Sistema“ software tool.

Communication

In mechanical engineering, a wide variety of components and systems must be networked to allow the exchange data with each other. It is not uncommon for older communication standards to appear because existing, proven devices should continue to be used.

k-tech helps you to combine a wide range of communication channels in one system and, thus, to provide you with a compact and efficient solution. In addition to the traditional bus systems, we also offer the use of serial communication and Windows-based file management:

Bussystems, serial communication & data management

- Profinet

- EtherCAT

- IO-Link

- CANopen

- TCP/IP & UDP (über LAN / WLAN)

- OPC-UA

- XML-, CSV-, INI-, TXT-Dateien (Windows-basiert)

- Serielle Kommunikation, z.B. RS232, RS422, RS485 etc.

- DeviceNet

- Ethernet/IP

- ASI Bus

Digital transformation / digitization

Terms such as „Smart Factory“, „Industry 4.0“ or „Big Data“ are commonplace and, are becoming increasingly important. The objective: a self-organized production where people, machines, logistics and products cooperate directly with each other and thus make it much easier to optimize the entire value chain. Better resource and production planning, shorter production times, networking of distributed resources, connection to an ERP system, an increase in the degree of automation and the integration of learning systems are just some of the advantages provided by this new development.

To provide you with the best possible support in digitization, k-tech relies on transparency for special machines and provides the required data via an interface. It does not matter whether the system is to be connected to a control system, an ERP system, or a customer-specific solution. Due to our wide range of interfaces, we comply with your requests and, are happy to help you make the required data available in a simple way.