Our production – high competence meets a large scope of performance

Whether plant construction, series production or prototyping: together we will find your solution

With k-tech, you have a partner at your side who functions as an „extended workbench“ to provide you with individual assemblies or completely manufactured and tested series products. In our production, your own ideas are turned into reality and your products are manufactured. For this purpose, we use the latest methods, tools, CNC production technology, CAM systems and much more.

CNC production

With a comprehensive range of CNC-controlled machining centres and lathes, k-tech relies on CNC-supported production. Our continuous expansion allows us to respond to the steadily increasing requirements.

Using our CAD-CAM software Visual-Mill, we have been using not only in 2D but also 3D design for a long time – the basis for the development of a modern, associative production process. With the introduction of SolidCam, a new CAD-CAM software, one of the cutting-edge production tools on the market was integrated. The direct adaptation with the existing design programs allowed us to create a complete system.

Now, we can guarantee a direct link from the individual component or assembly to the processing machine in production. Design adjustments and changes are reported directly and can be incorporated into the production process. This modern process helps us to ensure our quality standard. This is an essential part of our quality management.

Tool making

If you entrust us with tool making, you will benefit from our long-term experience gained from applications in a wide variety of industries. In combination with state-of-the-art technology, we offer you absolute reliability and a high-quality standard.

Our machinery includes 3- and 5-axis machining centres, CNC lathes, grinding machines and wire eroding machines.

In tool making, we offer the following portfolio:

- punching tools

- cutting tools

- progressive die tools

- bending tools

- sawing tools

- and much more

Prototyping

We would be happy to work with you to implement your idea in the field of assembly and equipment construction. From the development of a prototype to series production, we accompany the entire development process. k-tech can develop the complete or partial prototyping for you.

In addition to development, production, assembly and wiring, the k-tech team of experts can also take on test runs, optimizations, QA protocols and documentation.

Series products

k-tech combines all the skills they need for the successful manufacture of series products. Both for our own production and, of course, for the series products of our customers.

In addition to the mere production of the series products, we also take on commissioning, service, repairs, spare parts, and documentation at your request. In addition, we support you in sales, logistics, maintenance, and device testing (TÜV, UL, VDE). We also assist you with our know-how when it comes to patent research and application.

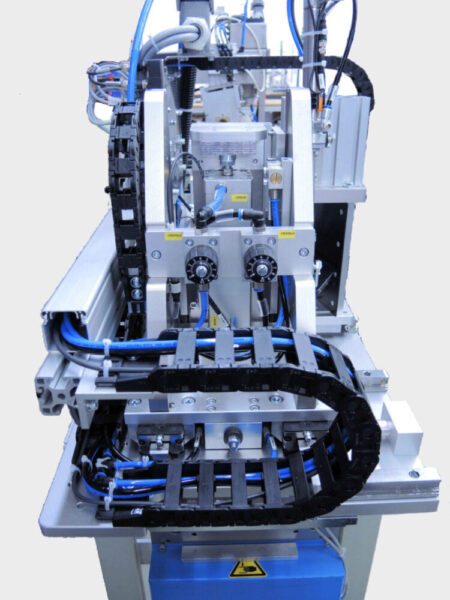

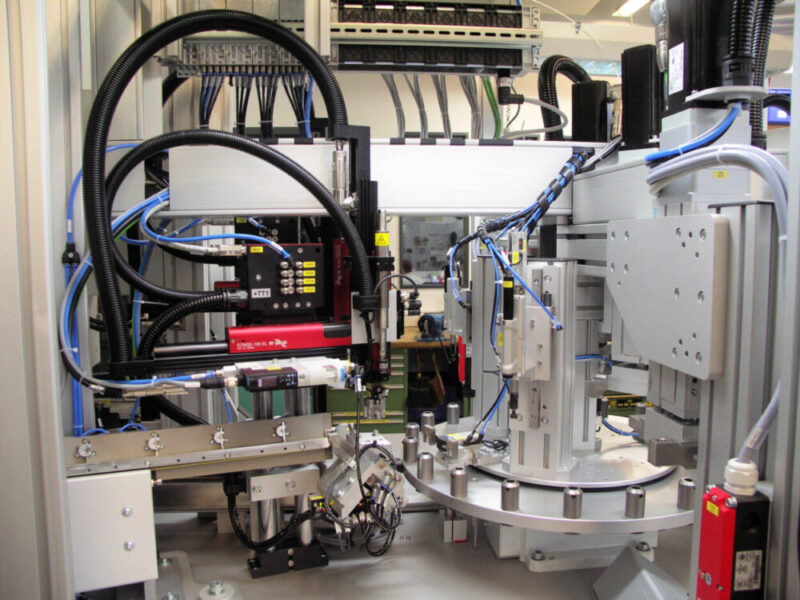

Mechatronik systems & assemblies

Mechatronics is definitely one of our hobbyhorses. The interaction of mechanics, electrics and IT does not only take place in our production machines and special machines, but also in series machines and series products.

We can offer you an all-round solution. k-tech handles the entire process for you.

Our work processes include

- Organization, planning and ordering

- Manufacturing and unit assembly

- Cable manufacture and control engineering

- Wiring and testing according to VDE

- Test software and tools

- Settings and functional testing

- Casings

- Quality and acceptance reports

- Packaging

- Logistics

Special machine construction

As the name suggests, special machine construction produces custom-made products. Each machine is specially designed for you and your needs. Our employees can draw on many years of experience as a complete system supplier in the various business areas. This know-how paired with proven processes, technologies and synergies is our guarantee to develop an innovative and custom special solution. Our task does not end with the manufacture and delivery of the system. We also support the new machine operator with the integration of the special machine in production, including the interfaces to additional merchandise management systems, etc. The safety checks and documentation are of course part of the system.

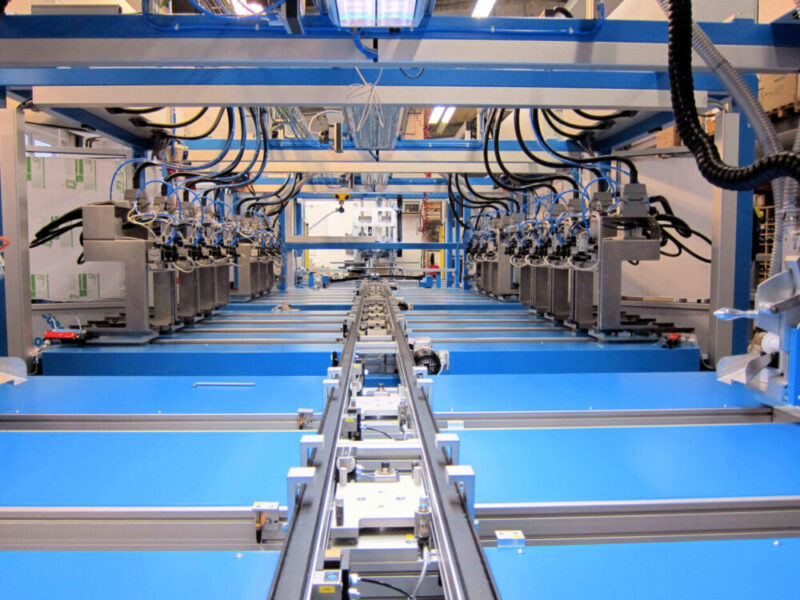

Plant construction

Our competence does not end with mechanical engineering. The construction of a complete system is also part of our daily business. As a general contractor, we develop and build specific special plants for our customers for a wide variety of applications and areas.

Our plant construction portfolio includes the following applications

- Bottling plants

- Conveyor systems

- Handling systems

- Measuring systems

- Robot systems

- Assembly systems

- Production facilities

- Test systems

- Cleaning systems for dry applications

- Sorting systems

- Cycle systems

- Transfer systems

- And many more

Manufacturing

In our production department; we produce single parts and small series, both for contract manufacturing and for our own use. Thanks to short, internal routes and the wide range of machinery, we can respond flexibly to your customer requests and delivery times.

Among others, our manufacturing skills are the following:

- 3- and 5-axis milling

- CNC turning

- Wire EDM

- Measuring

- Grinding

- Welding

- And more

Service, repairs and spare parts

To ensure a long service life of your machines and systems, we recommend carrying out service, inspections and maintenance work. k-tech has its own, flexible service team that carefully and professionally takes care of maintenance work on site. Our service team can also service third-party systems and support you in the procurement of spare parts.

We would be glad to conclude an appropriate maintenance contract with you.

Quality management

The QM department creates the basis for recording, defining, and optimizing processes and procedures in the company and in turn lays the foundations for service or product quality. Since 2012, k-tech has had its own central quality management system based on ISO 9001. Our internal quality management is regularly assessed and accepted in various customer audits from various industries. A medium-term certification of our quality management is planned.