Our machines for your business area

k-tech can be found everywhere – from automotive via aerospace to the pharmaceutical and semiconductor industry

Since the foundation of our company over 30 years ago, we have consistently developed our skills and services. We are now active with various services in a wide variety of industries. The overview below shows our scope of performance

Our business areas

Automotive

The automotive and mechanical engineering industries are among the key industries in Europe, especially in Germany. Thanks to our many years of experience as a machine and system manufacturer, we can support our customers with comprehensive and demanding technical requirements.

k-tech has already used the following machines and assembly systems:

- Single part and small-batch production

- Tool making and fixture construction (punching, sawing, bending, drilling, etc.)

- Individual / assembly workstations

- Gripper and clamping systems

- Feeding, separating and sorting systems

- Machining and assembly of profile seals

- Input and output stations

- Surface and edge cleaning systems

- Cleaning of product units in the range of <500 µm

- Integrable cleaning cells with the latest cleaning technology for components and load carriers

- Assembly systems and assembly lines

- Pick & place and handling systems

- Robotic systems

- Rotary indexing tables / automatic rotary indexing machines

- Transfer systems and cycle systems

- Test equipment

- Marking and labelling

- Measurement systems for quality assurance

- Functional test and EOL systems

- Retrofit

Food, Pharmaceutical & Medical

k-tech supports their customers in the implementation of individual requirements and develops customer-specific solutions. This also applies to the food, pharmaceuticals, and medical sectors. Here we use a wide variety of technologies to generate the optimal application systems for you.

k-tech has already implemented, among others, the following assembly systems, and machines in this area:

- Single part and small-batch production

- Manufacture and assembly of modules/devices and fixtures

- Fixture construction

- Gripper, clamping systems and holders or mould cavities

- Feeding, separating, and sorting systems

- Joining, positioning, press-fitting, or screwing systems

- Assembly systems (cycle systems, automatic rotary indexing machines, robot systems, etc.)

- Pick & place and handling systems

- Transfer systems and production lines

- Plants for filling, dosing, and weighing systems

- Technical cleanliness of machines according to USP788, VDI2083 and, ISO14644

- Integrable cleaning cells

- Solutions for the cleanliness of product surfaces or assembly-integrated cleaning systems

- Test systems for quality assurance

- Labelling and marking

- Marking and recognition systems for medical instruments

- Packaging and palletizing systems

- Retrofit

Semiconductors

In the semiconductor industry, precision is one of the most important factors to ensure a high-quality standard. To meet our high-quality standard, even the smallest component dimensions must interact perfectly. As we can guarantee this, we have already been able to acquire many well-known customers from the semiconductor industry. We are happy to assist you with our experience and support you in the implementation of your project.

We can also design the appropriate systems for your requirements. Our portfolio for the semiconductor industry includes:

- Single part and small-batch production

- Various mechatronic modules

- Input and output stations

- Handling systems

- Robot systems

- Manufacture and assembly in all manufacturing areas

- Manufacture and assembly of modules and systems in the field of reticle handling

- Manufacture and assembly of modules and systems in the field of wafer handling

- Process development, production and assembly of Reflow-Oven

- Integrable cleaning cells for the cleanliness of product surfaces

- And others

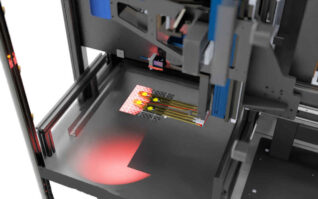

Electronics, sensors & optical systems

Special tasks sometimes require special machines and equipment. In such cases you can rely on the many years of experience of k-tech as an automation partner. In addition to complete robot solutions, production and assembly systems, cleaning systems for technical cleanliness are also gaining in importance.

Our wealth of experience in electronics, sensors and optical systems includes:

- Manufacture and assembly of modules/devices and fixtures

- 3D scanner and camera

- Contacting devices

- Tool making and fixture construction

- Test and adjustment devices

- Individual workstations

- Gripper and clamping systems

- Feeding, separating and sorting systems

- Joining, positioning, press-fitting or screwing systems

- Gluing, dispensing, sealing and weighing systems

- Drilling, punching and bending systems

- UV gluing system

- Ultrasonic cleaning systems for piezo elements

- Surface and edge cleaning systems

- Integrable cleaning cells

- Solutions for the cleanliness of product surfaces or assembly-integrated cleaning systems

- Technical cleanliness of machines according to VDA 19

- Laser welding systems

- Process integrations

- Assembly systems (cycle systems, automatic rotary indexing machines, robot systems, etc.)

- Pick & place and handling systems

- Testing, programming and calibration systems

- Labelling and marking

- Measurement systems for quality assurance

- Functional test and EOL systems (end-of-line)

- Packaging

- Retrofit

Aerospace

The aerospace industry not only bridges great distances but is also of considerable importance for the German economy. k-tech is proud to be part of it. We will be glad to support you in developing this important area. Our test systems ensure safety and reliability.

Our aerospace portfolio includes:

- Single and small-batch production

- Tool making

- Complete assemblies

- Series products

- Test equipment & testing devices

- Feeding and sorting systems

- Complete handling & testing systems

- Pick & Place systems

- Quality assurance / handling systems

- String measurement

- Gripper systems

- Sunlight simulator

- Flasher

- Goniometer

- Conveyor lines

- Production of digital test systems for more efficient damage detection in the aircraft outside area

Solar & photovoltaics (PV)

Under the increasing pressure of climate change, more and more people and companies around the world are turning to the sun as a source for generating electrical energy. As a system supplier, we have been developing and producing assemblies, test and handling systems for the PV sector for many years.

Our portfolio in the solar and photovoltaic sector includes:

- Single part and small-batch production

- Control cabinet series production

- Manufacture and assembly of modules/devices and fixtures

- Tools

- Feed systems

- Handling systems

- Alignment systems

- Pick & Place – systems

- Quality assurance handling systems

- Quality measurement systems

- Test equipment

- Lighting units

- Conveyor lines

- Sun testers

- Technical cleanliness of machines

- Integrable cleaning cells

- Solutions for the cleanliness of product surfaces or assembly-integrated cleaning systems

- And others

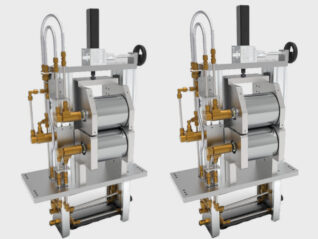

Test equipment construction

k-tech not only realizes assembly and production systems for their customers but also integrates the quality assurance process. We can carry out these functional tests either as intermediate steps or at the end of the manufacturing process. We would be glad to support you with your next project. All relevant information on the subject of automated testing technology at k-tech can be found here.

Our portfolio for test equipment construction includes:

- Single part and small-batch production

- Manufacturing and assembly of small appliances

- Custom test adapters

- Contacting device

- Feeding, separating and sorting systems for micro-components

- Joining, positioning, press-fitting or screwing applications

- Handling and assembly of micro-components

- Calibration systems for magnetic coil sensors

- Measurement systems for quality assurance

- Assembly systems (cycle systems, automatic rotary indexing tables, robot systems, etc.)

- Functional test

- EOL test (End of Line)

- Retrofit

- For more technologies, refer to our Technologies section

Recyling

In the field of recycling, we have developed several systems for taking back deposit containers (cups, bottles, etc.). We design and develop individual modules according to custom requirements.

Our portfolio includes:

- Take-back systems for disposable and reusable cups

- Cruncher (compactor) for PET and AL containers for bottle deposit-refund systems

We would be happy to advise you and find an individual solution for your needs. For further information, refer to our own brands and partners section

Sports

We are pleased that k-tech is allowed to work, among others, in the areas of soccer, ice hockey, cycling, trekking, American football and winter sports. We have developed a heating system for Thermofit components, which adapts the fit of the sports shoes to the respective athlete in the shortest possible time. For further information, refer to our own FormBase brand.

Other areas

As an experienced system supplier, we can design the technologies and synergies from the various industries and use them in other business areas. Whether for applications from plastics technology, household, gastronomy, home improvement or the like – we look forward to implementing the application with our customers.

Our production park includes a wide range of different machines, enabling us to manufacture even the most complex assemblies for you and with you.

Our various projects from different areas include:

- Single part and small-batch production

- Manufacture and assembly of modules/devices and fixtures

- Fixture construction

- Shaping of carbon fibre extrudate with winding (plastics industry)

- Handling system for grinding systems (paper industry)

- Handling between different transport systems (beverage industry)

- Assembly lines, individual workstations, tools for pump and block systems (hydraulics)

- Advertising material for testing and demonstrating products in the customer area (marketing)

- Automatic assembly machines (household)

- Modular assembly line for pumps and block systems (hydraulics)

- EOL tests (hydraulics)

- Robot integration of processing machines such as lathes and milling machines (industry)

- Safety upgrade for existing systems according to current regulations (industry)

- Test systems for quality assurance (industry)

- Labelling and marking (industry)